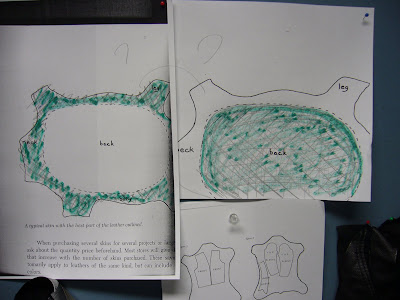

I then tried layering the pieces, in the way that I imagined that the rapid prototype printer would layer up the material as it prints, albeit on a much larger scale! It really was not successful as it just affirmed the problems with using the waste as it is and trying to get pieces to relate to each other.

Out of frustration I picked up some small random leather scraps and mashed them together like a hamburger with the silicone acting as a binder. It is kind of cool and sticks together really well when dry, however there are still massive limitations to this, again the leatherness is lost. What I'm creating here also is like a composite leather - a downcycling of the resource. The other problem I see with these tests, is that it relies on the introduction of another material element, whereas my aim is to find the inherent potential in the material as it is, without relying on something that completely changes it's properties.

Out of frustration I picked up some small random leather scraps and mashed them together like a hamburger with the silicone acting as a binder. It is kind of cool and sticks together really well when dry, however there are still massive limitations to this, again the leatherness is lost. What I'm creating here also is like a composite leather - a downcycling of the resource. The other problem I see with these tests, is that it relies on the introduction of another material element, whereas my aim is to find the inherent potential in the material as it is, without relying on something that completely changes it's properties. Alongside these tests, I made up a model with some strips of leather (scraps from cutting away waistband excess) - this was to demonstrate what I thought would be possible to model in 3D, of course on a large scale. I modelled the strips over a can, in a woven structure, and then removed the can when the silicone was dry.

Alongside these tests, I made up a model with some strips of leather (scraps from cutting away waistband excess) - this was to demonstrate what I thought would be possible to model in 3D, of course on a large scale. I modelled the strips over a can, in a woven structure, and then removed the can when the silicone was dry.

I reflected on these tests about 2 weeks after making them and asked some questions...

Why does this last model collapse?

It collapses because I let it go....but the main reason is because the can is no longer there. The can is like the body...and this is kind of how it works in 3D modelling i.e. you need to model the can too.

The negative space is AS important as the positive. It is what is not there that allows articulation and the ability to react. As well as the can not being there, it is the space between the woven structures that enables reactivity. This is the big problem with the earlier siliconed samples - there is no space, no way for the particles to "speak" and interrelate with each other. This takes me back to the John Jones leather animation - the pieces have independence but speak to each other to create a whole. Otherwise, the pieces become part of an amalgam, like this Japanese pancake where the individual ingredients are difficult to discern.